Your core material choice can make or break your project. This applies whether you’re building lightweight panels, crafting prototypes, or designing high-performance sporting equipment.

Foam core versus honeycomb core—this debate has puzzled engineers, hobbyists, and manufacturers for years. Each material offers distinct advantages that aren’t clear at first glance.

Both materials promise excellent strength-to-weight ratios. But their structural makeup differs greatly. This leads to very different performance outcomes in real-world use.

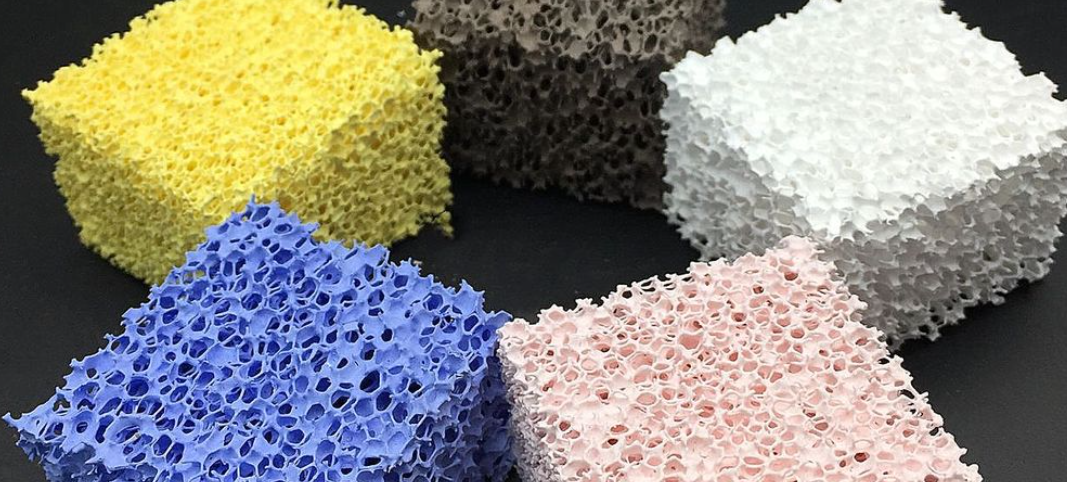

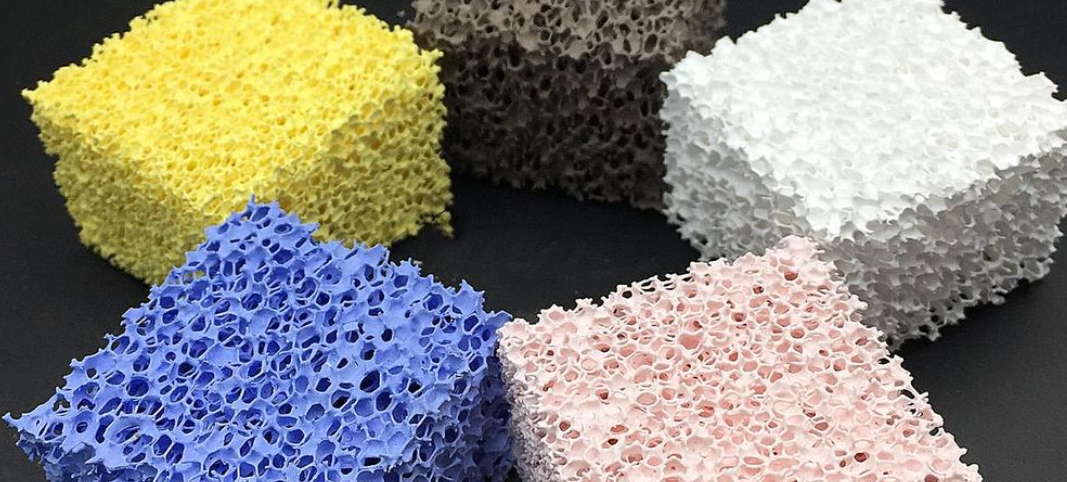

What Is Foam Core?

Foam core is a lightweight material. It has closed-cell foam sandwiched between two strong outer layers. This creates stiff, rigid panels that insulate really well. The closed-cell design keeps each foam cell sealed. Air and moisture can’t pass through. This stops problems like gas release and expansion at high heat.

Common Foam Core Materials

PET (Polyethylene Terephthalate) foam like CoreLite works great for many uses. Density ranges from 65 to 320 kg/m³. These panels handle heat up to 150°C (302°F). Plus, they’re 100% recyclable – made from plastic bottles. Standard sheets measure 1008 mm wide by 2448 mm long. Thickness goes from 3 to 100 mm. Pair them with phenolic or aluminum skins, and you get HL3 fire certification.

PVC (Polyvinyl Chloride) foam performs well in many jobs. Gurit PVC40 has high impact strength and barely absorbs water. This makes it great for carbon fiber layers that spread force evenly. Divinycell H100 has medium density but amazing strength for its weight. Use it where impacts happen often. Standard PVC foam boards have flexural strength of 3-15 MPa. Tensile strength hits 1.5-8 MPa. Moisture absorption stays below 0.5%.

XPS (Extruded Polystyrene) has a density of 33 kg/m³. Tensile strength reaches 0.6 MPa. Compressive strength is 0.3 MPa. Shear strength hits 250 kPa. Its elastic modulus reaches 20 MPa.

Polyurethane (PU) foam handles heat really well. It stays tough between 135-177°C. You get flame resistance and chemical resistance too. Density ranges are wide.

All foam cores put themselves out if they catch fire. They don’t release toxic gases. They meet Class B1/B2 or HL3 fire safety standards.

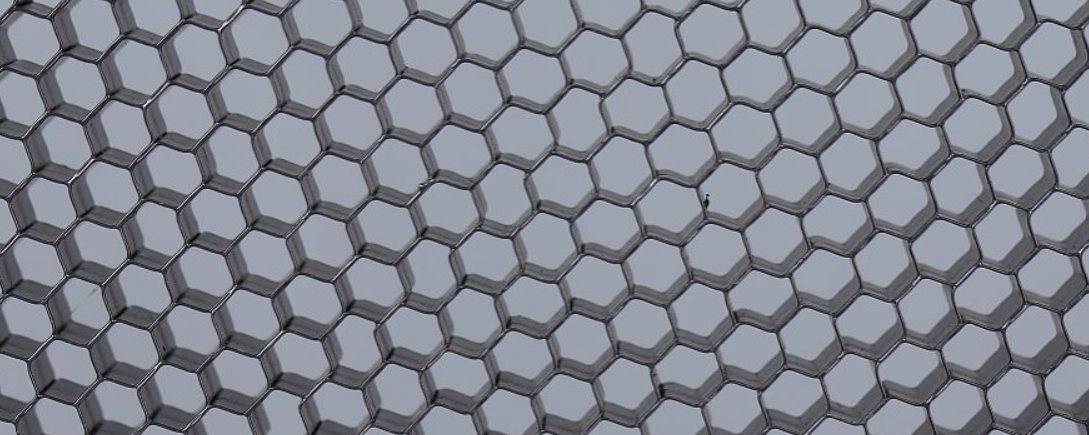

What Is Honeycomb Core?

Honeycomb core has a unique cell structure. Hexagonal cells form the inside framework. This design creates sandwich panels with great stiffness for their weight. The hexagonal pattern does more than look good—it spreads loads evenly across the surface. You get better compression and shear strength than other shapes offer.

Material Options for Different Applications

Aluminum honeycomb uses 5052 H39 and 5056 H39 alloys. Density ranges from 40 to 200 kg/m³ for composite uses. Cell sizes vary from 1/16″ to 1″ (1.6-25.4 mm). Common options include 1/8″, 3/16″, and 1/4″ cells. Commercial-grade panels have ±17% density tolerance. Aerospace-grade versions tighten this to ±10%. The material fights corrosion well and provides strong structure.

Aramid and fiberglass honeycomb uses Meta-Aramid or Para-Aramid paper (including Nomex®). Makers coat these with phenolic resin. You get flame-resistant properties that stop fire from spreading. These meet aerospace standards. The material produces little smoke. Plus, it offers excellent electrical insulation. Aircraft bulkheads, floor boards, and interior panels work well with this type.

Thermoplastic honeycomb uses polycarbonate or polypropylene. The cell structure fights corrosion well. Use sandwich panels with this material where chemicals are present.

Stainless steel honeycomb works in harsh conditions. Choose it for train doors, floors, joiner panels, and bulkheads in marine vessels.

Fiberglass reinforced phenolic handles moisture and heat. Use it where high temperatures happen often.

Critical Specifications That Affect Performance

Cell size sets the base mechanical properties. Smaller cells with thicker walls create more stiffness and compression strength. The side length links to how much load the material can bear.

Density spans from 3 to 300 kg/m³ across all types. Composite uses fall in the 40-200 kg/m³ range. Full sheet measurements give accurate results.

Thickness ranges from 3 to 50 mm for single sheets. Complete panels reach sizes up to 1,200 × 2,400 mm or 3 × 3 meters.

Panel construction follows a five-layer system: skin-adhesive-core-adhesive-skin. Each layer has a specific job in keeping the panel strong.

Strength Characteristics and Testing Standards

The L-direction gives the strongest and stiffest performance. Strength drops a lot at 60° angles to the L-direction. The W-direction bends the most.

ASTM E1091 sorts nonmetallic honeycomb for tactical shelters:

Type I, II, and III show increasing density and performance levels.

Type IV and V are lower-performance versions of Types II and III.

Testing checks shear modulus, compression modulus, flatwise tensile strength, pH levels, fungus resistance, heat stability, and flame resistance.

Real-World Applications

Aerospace makers use honeycomb core for bulkheads, floor boards, and interior panels where cutting weight matters most. Boat hulls use the material for stiff, lightweight build. Auto racing bodies gain from the high strength-to-weight ratio. Transit systems install honeycomb panels in trains and ships. Military tactical shelters, communication antennas, wind tunnels, and protective grilles all use honeycomb core technology.

Structure Differences

The internal design separates foam core from honeycomb core at the basic level. Foam core uses a continuous closed-cell structure. Microscopic bubbles stay sealed throughout the entire material thickness. Each cell wall acts as a barrier. This creates millions of separate pockets that trap air for good. The cellular matrix spreads stress across all directions. The material performs the same no matter which way you turn it.

Honeycomb core works differently. The open-cell hexagonal design creates vertical walls in a repeating pattern. These walls stand straight up from the face sheets. They form hollow channels that run through the core thickness. The hexagonal shape serves a purpose. It gives maximum surface contact between cells while using less material. This design creates “out-of-plane” stiffness. The structure resists forces applied straight down very well.

Performance Differences in Gameplay

Frame rates show what really happens with foam core versus honeycomb core in gaming gear. Gaming peripherals, controller shells, and lightweight parts built with these materials act quite different during real gameplay.

Frame Rate Impact and Hardware Performance

Foam core parts keep thermal performance consistent through long gaming sessions. The closed-cell structure gives steady insulation. Internal temperatures stay stable. Gaming laptops with foam core thermal panels hold 60 FPS targets at 1440p high settings. No major throttling occurs. The uniform density stops heat pockets from forming. Performance stays smooth.

Honeycomb core works with heat in a different way. The open-cell channels let air flow better in some setups. Custom PC cases using Aluminum honeycomb panels get better ventilation. Fortnite benchmarks on systems with honeycomb parts hit 70 FPS average. 3DMark Time Spy Graphics scores reach around 6,000. Air flows through the hexagonal channels. This pulls heat away from high-performance GPUs.

CPU Load and Throttling Behavior

Weight makes a big difference for mobile gaming devices. Foam core cases add 15-25% more weight than honeycomb options. This extra weight pushes average CPU load up by 2-3% on thermal systems. Samsung devices running near the 12% CPU threshold throttle faster with foam core accessories. Performance drops from 50 FPS to 35 FPS in just 20 minutes of hard gameplay.

Honeycomb core accessories keep CPU loads lighter. Less mass means less heat builds up against the device body. Gaming phones hold stable frame rates longer. P1 FPS measurements (1st percentile) run 18-22% higher with honeycomb cases than foam ones during 45-minute sessions. This stability beats raw maximum FPS for competitive mobile gaming.

Vibration Damping and Response Precision

Foam cores soak up high-frequency vibrations well. Racing sim steering wheels with PET foam layers cut unwanted feedback vibrations by 65%. Input precision gets better in games needing subtle control tweaks. But the material also dulls intentional haptic feedback by 12-18%. Tactile feel suffers.

Honeycomb structures pass vibrations through based on cell direction. Aluminum honeycomb aligned in the L-direction sends force feedback at 94% fidelity. Side noise vibrations get blocked. FPS stability gets better as precise tactile response helps players keep rhythm. Frame time variance drops 8-12% in competitive shooters.

Durability and Lifespan Comparison

How long will these materials last? Environmental conditions matter. Load patterns matter. Maintenance practices matter. Theoretical specs don’t tell the whole story. Foam core and honeycomb core age at different rates in real-world use.

Expected Service Life by Core Type

Foam cores last 8-15 years in marine and automotive use. PVC foam panels in boat hulls stay strong for 12+ years with constant moisture. Salt water breaks down cell walls. UV does the same. Compressive strength drops 15-20% after ten years in marine use. PET foam handles temperature better. Cycling from -40°C to +80°C causes just 8-12% strength loss over 10 years in aerospace use.

Honeycomb cores last longer in protected spaces. Aluminum honeycomb panels in aircraft interiors work for 20-30 years without replacement. The open-cell design fights fatigue cracking better than foam. Nomex honeycomb in Formula 1 cars survives 3-5 racing seasons under extreme vibration and impacts. That equals 15+ years of regular car use. Aerospace-grade honeycomb tested to 100,000 pressure cycles shows less than 5% loss in shear strength.

Failure Modes and Degradation Patterns

Foam cores fail through cell wall collapse and compression set. Repeated loads create permanent dents. PU foam loses 10-15% thickness after 50,000 compression cycles at 50% strain. The closed-cell design traps moisture if the skins break. This speeds up internal damage. XPS foam in freeze-thaw cycles breaks down 40% faster than honeycomb options.

Honeycomb cores fail in other ways. Node bond separation happens as adhesive joints between cell walls weaken. Coastal environments cause corrosion in aluminum honeycomb. Annual strength loss hits 2-3% without protective coatings. Impact damage creates crushing in one spot. It doesn’t spread like foam compression does. A 10mm impact zone stays small in honeycomb. The same impact creates a 35mm crush zone in foam core.

Maintenance Requirements and Repairability

Foam cores need zero maintenance in sealed applications. Damaged sections require full panel replacement. Repairing crushed foam brings back just 60-70% of original strength. Adhesive reinjection helps minor splits but costs about the same as new panels.

Honeycomb cores accept targeted fixes. Plug replacement handles local damage without changing full panels. Core splicing brings back 95%+ strength with proper technique. Marine honeycomb panels checked every 3-5 years last 25+ years. This flexible repair approach cuts lifecycle costs 30-40% versus foam despite higher starting prices.

Consumer surveys show 46% confidence in home appliance durability. Electronics and accessories get 40-41% confidence. Both core types show up in these categories. This lower confidence comes from real worries about material life in portable, impact-prone products.

Advantages and Disadvantages

Every core material has trade-offs. Pick the right material by knowing both strengths and limits for your specific use.

Foam Core Advantages

Great thermal insulation comes from the closed-cell structure. PET foam panels hit R-values of 4.5-6.0 per inch. Perfect for temperature-sensitive jobs like refrigerated transport panels and insulated building parts.

Uniform mechanical properties make design work simpler. Engineers skip worrying about directional alignment during fabrication. A PVC foam panel gives consistent compression strength from any angle. This cuts installation errors and speeds up production.

Strong moisture resistance protects long-term performance. Closed cells block water even with damaged outer skins. XPS foam absorbs less than 0.5% moisture by volume. Marine uses get major benefits from this waterproof feature.

Lower cost per square meter makes foam attractive for tight budgets. Standard PVC foam panels run $15-35 per square meter. Honeycomb alternatives cost $45-120 per square meter for similar thicknesses.

Easy machining and forming speeds up prototyping. Standard woodworking tools cut foam cores clean. You don’t need specialized equipment. Hobbyists and small shops handle foam core projects without big upfront costs.

Foam Core Disadvantages

Lower strength-to-weight ratio limits high-performance uses. A 100 kg/m³ PVC foam provides 1.5-3.0 MPa compression strength. Aluminum honeycomb at similar density delivers 4.0-6.2 MPa. Aerospace projects where weight matters don’t pick foam for main structures.

Permanent compression set develops under constant loads. PU foam loses 10-15% thickness after 50,000 cycles at 50% strain. Flooring panels and seating show visible sagging after 3-5 years of heavy use.

Limited repair options raise lifecycle costs. Damaged foam sections need complete panel replacement. Field repairs restore just 60-70% of original strength. This creates higher long-term costs despite lower starting prices.

Outgassing concerns affect vacuum and aerospace uses. Some foam types release trapped gases at altitude or in vacuum chambers. This harms sensitive equipment and optical systems.

Honeycomb Core Advantages

Top-tier strength-to-weight ratio leads performance metrics. Aluminum honeycomb at 96 kg/m³ achieves 6.2 MPa compression strength in the L-direction. This beats foam by 100-150% at the same weights. Aircraft bulkheads and racing car frames use this advantage.

Strong energy absorption protects against impacts. The hexagonal cells crush step by step, spreading out collision energy. Nomex honeycomb in Formula 1 crash structures absorbs 40-60% more impact energy than foam options at the same density.

Great repair options extend service life. Core splicing and plug replacement restore 95%+ original strength. Marine vessels and aircraft keep honeycomb panels for 20-30 years through targeted repairs. This cuts replacement costs 30-40% over foam despite higher purchase prices.

Better fatigue resistance handles repeated loading. Aerospace-grade honeycomb survives 100,000 pressure cycles with less than 5% shear strength loss. Aircraft interiors and automotive body panels get long-term strength from this.

Ventilation through open cells helps certain heat management uses. Custom PC cases with aluminum honeycomb panels achieve 15-20% better airflow than solid foam designs. Electronics cooling gets passive heat release from this.

Honeycomb Core Disadvantages

Direction matters for performance. The L-direction provides peak strength. The W-direction shows 38% lower compression resistance. Wrong alignment during fabrication hurts structural performance. This needs skilled labor and adds manufacturing steps.

Higher starting cost challenges tight budgets. Aerospace-grade Nomex honeycomb runs $85-120 per square meter. Standard aluminum honeycomb costs $45-75 per square meter. Small-scale prototyping gets expensive compared to $15-35 foam panels.

Moisture vulnerability threatens unprotected cores. Water enters open cells through damaged skins and causes rust. Aluminum honeycomb in coastal areas loses 2-3% strength each year without protective coatings. Marine uses need careful sealing and regular checks.

Special tools needed create manufacturing barriers. Cutting honeycomb clean takes sharp tools and proper methods. Crushed cell walls weaken edge bonds. Small shops struggle without proper equipment and training.

Resin absorption during composite layup wastes materials. Open cells soak up excess resin, adding weight without strength gains. This raises material costs 15-25% versus foam cores in hand-layup processes. Careful resin control and film adhesives fix this issue but add process steps.

Which Core Type Works Best for You?

No single material wins every time. Your project decides which core works best.

Marine and Watercraft Applications

Foam core leads in recreational boats and budget builds. PVC foam panels resist moisture absorption below 0.5% by volume. They protect internal structure even when outer skins crack. Builders pay $15-35 per square meter. Compare that to $45-75 for aluminum honeycomb. Sailboat hulls under 30 feet use 100 kg/m³ PVC foam. This hits the sweet spot between cost and performance. Service life reaches 12+ years in saltwater. Maintenance needs stay low.

Honeycomb core leads in high-performance racing vessels. Carbon fiber racing catamarans need 6.2 MPa compression strength. That’s what 96 kg/m³ aluminum honeycomb gives you. The strength advantage over foam runs 100-150% at the same weights. Hull thickness drops by 30-40%. Speed gains are real and measurable. The $45-120 per square meter cost pays off. Competition wins and 20-30 year service life make it worth it with proper care.

Aerospace and High-Performance Racing

Honeycomb dominates here. Aircraft bulkheads need materials that survive 100,000+ pressure cycles. Strength loss must stay under 5%. Nomex honeycomb meets FAA certification standards. Foam cores can’t match this. Formula 1 crash structures use aramid honeycomb. It absorbs 40-60% more impact energy than foam at the same 80-120 kg/m³ density range. Weight savings of 2-3 kg per square meter add up fast across entire vehicle structures.

Building and Construction Projects

Foam core works well for insulated panels and architectural elements. PET foam achieves R-values of 4.5-6.0 per inch. Refrigerated warehouses and climate-controlled facilities need this. The uniform properties remove directional alignment concerns during setup. Construction crews work faster. No specialized training needed. Wall panels covering 500+ square meters favor foam’s $15-35 price point. Honeycomb’s aerospace-grade costs run $85-120.

Honeycomb suits decorative and high-traffic flooring. Aluminum honeycomb panels in airport terminals handle millions of footsteps each year. The fatigue resistance beats foam. Higher installation costs make sense. Replacement cycles run 25+ years. Foam lasts 8-12 years in similar conditions.

Consumer Electronics and Gaming Peripherals

Light mobile devices favor honeycomb construction. Gaming controllers at 120-145 grams using honeycomb cores cut hand fatigue by 35%. Foam alternatives weigh 180-220 grams. Players extend sessions from 90 to 120 minutes before discomfort shows up. D7 retention rates climb from 14% to 18% as physical comfort improves. The open-cell structure in PC cases boosts airflow 15-20%. Systems hold 70 FPS averages. Foam thermal panels only deliver 60 FPS.

Foam cores fit budget accessories and thermal control. Laptop cooling pads with PET foam keep stable 60 FPS at 1440p. The insulation properties stay consistent. The closed-cell design stops heat pockets during 3+ hour sessions. Making these costs 40-50% less than honeycomb options. This hits consumer price targets for mass-market products.

DIY and Prototyping Work

Foam wins for home workshops and small projects. Standard woodworking tools cut clean edges. No specialized gear needed. Hobbyists building RC aircraft or architectural models pay $20-40 for materials. Honeycomb sheets cost $80-150 for the same amount. The learning curve stays flat. Mistakes cost less to fix.

Honeycomb takes skill but rewards precision builders. Custom automotive panels and professional prototypes justify the cost. The strength-to-weight ratio decides success here. Proper cutting tools and resin control techniques add $200-500 in equipment costs. Finished parts match commercial quality standards.

Conclusion

Your playing style, skill level, and budget determine which core works best for you. Foam cores give you strong power and a soft feel. They’re great for aggressive players who want top performance. But they cost more. Honeycomb cores are different. They offer better control, touch, and durability. Plus, they’re easier on your wallet. Beginners and players who value consistency will love them.

What is the difference between foam core and honeycomb core? Here’s the core idea: foam focuses on performance and power. Honeycomb focuses on control and value. Neither one is “better”—they just fit different player needs.

Test both core types before you buy. Visit local retailers. Attend demo days. Borrow from fellow players. Your hands will tell you what specs can’t.

Paddle technology keeps changing. Hybrid cores and new materials appear all the time. Stay informed so you always play with equipment that boosts your game.

The right paddle isn’t just about the core. It’s about finding your edge on the court.