I’ve looked at small metal parts that cost more than big car parts. Both are metal, but the price difference puzzles many people.

Metal injection molding and die casting are not just about shape or size. Each process works differently with materials. They also differ in precision and how fast they produce parts.

Process and Materials

MIM and Die casting use different methods. They also work with different materials.

Material Selection and Capabilities

MIM Material Range: MIM works with many materials. You can use stainless steel, titanium, tungsten, tool steel, nickel superalloys, cemented carbides, and precious metals. I recommend MIM for high-performance parts. These parts need strength, corrosion resistance, or special properties.

Die casting material Range: Die casting works with non-ferrous metals. These include aluminum, zinc, copper, magnesium, lead, pewter, and tin. It doesn’t work well with ferrous metals. It also struggles with materials that have high melting points.

Material Preparation

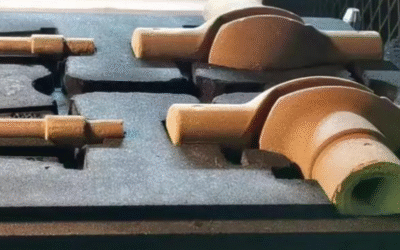

MIM Feedstock Creation: The process starts with powdered metal. We mix this powder with a polymer binder. This creates a feedstock. You get better control over material properties. You can also use metals with high melting points.

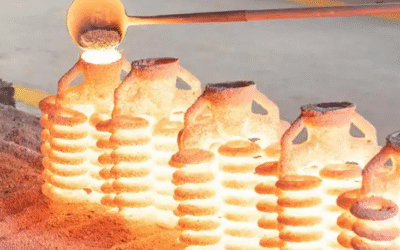

Die Casting Metal Melting: In die casting, we melt the metal. It becomes liquid. We inject it into a mold at high pressure. This works best with metals that have lower melting points.

Production Process Comparison

MIM Steps: MIM has several phases. First, we mold the feedstock. Next, we remove the binder. This is called debinding. Finally, we sinter the part. This makes the part dense and solid.

Die Casting Steps: Die casting is simpler. We melt the metal. We force it into a steel mold. The part cools. We eject the finished part.

Part Size and Detail

MIM Part Size: MIM makes small, detailed parts. Some are as small as 0.04″ to 0.12″. I suggest MIM for complex shapes.

Die Casting Part Size: Die casting works better for larger parts. Most parts range from 0.04″ to 0.2″.

Mold Durability and Surface Finish

- MIM Mold Longevity: MIM molds make several hundred thousand parts. This is their typical lifespan.

- Die Casting Mold Longevity: Die casting molds last longer. They can produce up to a million parts.

- Surface Finish: Die-cast parts have a smooth finish. They need less post-processing. MIM parts are different. They may need extra machining. They may also need surface treatments to get the finish you want.

Part Complexity and Design

I want to compare metal injection molding (MIM) and die casting. Part complexity and design flexibility are key differences between them.

Geometric Complexity & Design Flexibility

MIM handles very high geometric complexity. It can produce small parts with fine features, complex shapes, and hollow structures. I’ve seen it work well for parts with features smaller than 2 mm and wall thickness less than 0.5 mm. Die casting can’t match these capabilities.

Die Casting works best for parts with medium complexity. These parts are larger and heavier. It can’t produce thin wall sections below 0.5 mm or very intricate forms. Die-cast parts have simpler shapes. They also have thicker, stronger design structures.

Dimensional Accuracy and Tolerances

Both processes offer tight dimensional control. They can achieve accuracy up to ±0.05 mm.

MIM provides higher tolerances (1–2%) than die casting (2–3%). This consistency is why I recommend MIM for parts with complex shapes. It delivers repeatability across large production volumes.

Part Size and Weight

MIM works best for making small, lightweight parts. These are less than 100 mm in size and weigh under 100 g. I see it used often in medical devices, watchmaking, and precision electronics.

Die Casting is preferred for making larger parts. Products can range up to 750 mm × 750 mm and weigh over 10 kg. Common uses include automotive housings and appliance enclosures.

Surface Finish

MIM delivers fine surface finishes. It can achieve roughness as smooth as Ra 1 μm. This is ideal for parts needing detailed definition and minimal post-processing.

Die Casting parts come with a surface roughness of Ra 1.6–3.2 μm. They may need extra trimming or finishing for aesthetic or assembly purposes.

Wall Thickness Capabilities

MIM stands out for its ability to create very thin-walled parts (less than 0.5 mm thick). This comes from the nature of powder injection.

Die Casting struggles to maintain thinness below 0.5 mm. It excels in manufacturing thicker sections.

Part Complexity and Design Comparison Table

| Aspect | Metal Injection Molding | Die Casting |

|---|---|---|

| Part Complexity | Very high | Moderate |

| Min Feature Size | <2 mm | >2 mm |

| Wall Thickness | <0.5 mm possible | >0.5 mm (most cases) |

| Part Size | <100 mm (most cases) | Up to 750 mm or 10+ kg |

| Surface Finish | Ra 1 μm | Ra 1.6–3.2 μm |

| Production Volume | High (>10,000) | Very high (mass production) |

Which Method Should You Choose Based on Design Needs

Choose MIM if your project needs small, complex, thin-walled parts. You also want fine surface finish and tight dimensions. I recommend this for components in medical, luxury watch, or precision electronics sectors.

Choose Die Casting for larger, simpler parts. Production scale and lower unit cost are priorities here. This applies to automotive and large appliance manufacturing.

Production Volume: Comparing Output Capacity for MIM and Die Casting

Metal injection molding (MIM) and die casting both work well for high-volume manufacturing. But their ideal production ranges and cost efficiencies differ.

Optimal Production Volumes & Economies of Scale

MIM becomes most cost-effective when you produce over 10,000 units. The high initial tooling costs spread across many parts. I recommend MIM if your component needs reach tens of thousands or higher. It’s a strong choice for small, complex pieces.

Die Casting works for a broader range of volumes. It handles several thousand parts up to millions. Its molds are very durable. They often make up to one million parts. I find die casting attractive for both prototype runs and mass production.

Cycle Times and Production Speed

Die Casting: Die casting is very fast per part. Cycles run as short as 1–30 seconds. This depends on the part’s size.

MIM: Injection molding of the initial “green” part is quick. But the total process takes longer. Debinding and sintering extend the timeline over 25–30 days. This includes mold fabrication time.

Quick Reference Table: Production Volume Suitability

| Method | Economical Volume | Typical Part Size | Mold Life | Example Industries |

|---|---|---|---|---|

| MIM | 10,000+ units | 0.1–200 g (optimal <50g) | Several 100,000 parts | Medical, electronics, firearms, sensors |

| Die Casting | 1,000–1,000,000 units | 30 g–10 kg+ | Up to 1,000,000 parts | Automotive, appliances, machinery, large parts |

Key Takeaway:

I suggest you choose MIM for producing large quantities of small, complex, high-tolerance parts. It works best above 10,000 units per year. I recommend die casting if you need larger parts or larger batch sizes (thousands to millions). It’s also ideal for projects requiring both speed and mold longevity at any scale.

Strength and Weight: Comparing MIM vs. Die Casting

Let me break down the key differences between Metal Injection Molding (MIM) and Die Casting. Strength and weight are two major factors you need to consider. The materials and density levels make these processes quite different from each other.

Material Strength and Alloy Selection

MIM uses high-performance metals. These include stainless steel, titanium, nickel alloys, cobalt, and tungsten. These materials offer superior strength and hardness. They also resist corrosion and wear well.

Die Casting works with non-ferrous metals only. You’ll see aluminum, zinc, magnesium, and copper alloys. These metals provide moderate to high strength. But they are softer than MIM alloys.

Part Density and Its Impact

Density: Die cast parts reach 100% density. MIM parts achieve 95–99% density.

MIM parts have lower density. This has little effect on how they work. But it does reduce weight. This is good for applications that need lightweight yet strong parts.

Mechanical Performance: Hardness, Wear, and Creep Resistance

- Surface Hardness: MIM parts are harder than die cast parts. You can make them even harder through carburization.

- Wear and Corrosion Resistance: MIM beats die casting here. It offers superior resistance due to better materials and finer surface finishes (up to Ra 1 μm vs. die casting’s Ra 1.6–3.2 μm).

- Creep Resistance: MIM alloys resist creep well. This is true for nickel and cobalt-based alloys. They work great for load-bearing uses. Die cast alloys don’t perform well here.

Strength and Weight Comparison Table

| Process | Typical Materials | Max Density | Strength Level | Typical Part Weight | Surface Hardness | Corrosion Resistance |

|---|---|---|---|---|---|---|

| MIM | Steels, Ti, Ni, Co, W alloys | 95–99% | Very high | 15–20g (small/complex) | High | Very high |

| Die Cast | Al, Zn, Mg, Cu alloys | 100% | Moderate-high | 30g–10kg (small-large) | Moderate | Moderate |

Applications and Personal Insights

MIM is my top choice for products that need high strength, wear performance, low weight, and complex small shapes. I recommend MIM for medical device components and high-stress micro-parts. Based on my experience, it outperforms other methods in these areas.

Die Casting works best where density and part size matter more than maximum strength. Think large automotive and appliance components.

Precision and Surface Finish: Comparing MIM and Die Casting

I believe precision and surface finish separate metal injection molding (MIM) from die casting. These differences determine which method works best for your project.

Dimensional Accuracy and Precision

- MIM Precision: MIM achieves excellent dimensional accuracy. Tolerances reach ±0.05 mm. I recommend MIM for small and intricate parts. Fine details and exact measurements matter here.

- Die Casting Precision: Die casting offers similar precision at ±0.05 mm. This accuracy works best on larger parts. Less complex designs maintain this tolerance more easily.

I’ve seen MIM used for miniature gears, surgical instrument tips, and aerospace micro-locks. Perfect fit is critical. Small deviations cause failure. Die casting works better for automotive housings, electronics casings, and engine blocks. These parts need rapid production with reliable precision.

Surface Quality and Post-processing

- MIM Surface Finish: MIM parts come out of the mold with very smooth surfaces. They often achieve Ra 1 μm. This fine finish benefits high-cosmetic and precise functional applications.

- Die Casting Surface Finish: Die cast parts show surface roughness between Ra 1.6–3.2 μm. You often need post-processing. Trimming, powder coating, anodizing, or plating meet cosmetic or assembly needs.

I recommend MIM for biomedical implants and aerospace brackets. These need pristine surface quality. Die casting remains my go-to process for mobile device frames and large-scale industrial housings. You can treat the initial finish later if needed.

Density, Porosity, and Material Properties

- MIM Density and Porosity: MIM produces parts with 95–99% density. Some minimal porosity may exist. Mechanical properties match wrought metals, particularly for parts less than 50g.

- Die Casting Density: Die castings are completely dense. Porosity is nearly absent. This creates robust, heavier parts. Die casting suits components that need structural integrity at larger sizes (over 10kg).

Summary Table

| Feature | MIM | Die Casting |

|---|---|---|

| Precision | Excellent, ±0.05 mm | Good, ±0.05 mm |

| Surface Finish | Smooth, Ra 1 μm | Moderate, Ra 1.6–3.2 μm |

| Density | 95–99% | Complete density |

| Typical Part Size | Small, complex (15–20g) | Medium/large (30g–10kg+) |

| Post-processing | Often required for finish or tolerances | Often required to trim, finish |

| Use cases | Medical, aerospace, electronics | Automotive, consumer electronics |

Use Case Highlights

- MIM Applications: Biomedical implants, aerospace micro-brackets, electronics micro-connectors.

- Die Casting Applications: Automotive engine blocks, mobile device frames, industrial pump housings.

Production Volume Suitability

- MIM: I like MIM for small, complex parts at high volumes. Part weights run 15–20g. They seldom go over 50g.

- Die Casting: Die casting shines with large, simple parts. It handles parts over 10kg at very high volumes.

Optimization tip: For small-to-medium runs, tooling investment may cost more than you save per part. I suggest going for high volumes if you can.

Processing Speed: MIM vs. Die Casting Cycle Time and Throughput

The processing speed for metal injection molding (MIM) and die casting is quite different. This difference impacts which method works best in manufacturing.

Die Casting Cycle Times & Production Rates

Die casting offers fast cycle times. Most parts take 1–30 seconds, depending on size and complexity. A die casting operation can produce 1,000–1,200 parts per hour for small aluminum components. This method works well for mass production. I recommend it for automotive, aerospace, and consumer hardware industries. These sectors need large quantities and fast output.

Die casting handles both small and very large parts (up to 10 kg or more). It stays efficient across this range.

Metal Injection Molding (MIM) Processing Sequence

MIM has a fast initial injection stage (the “green part”). But the process slows down because of required debinding and sintering steps. These extra stages make overall cycle time for MIM much slower than die casting. For example, the total production cycle (including mold fabrication) can take around 25–30 days. Per-part throughput is limited by debinding and sintering speed. MIM produces thousands of parts per day. But the per-part rate is slower than die casting.

Based on my experience, MIM works best for small parts (15–20g) with complex shapes and tight precision. It focuses on quality, not per-hour output.

Head-to-Head Speed Comparison

Die Casting:

- 1–30 seconds per cycle

- Ideal for high-volume production of parts ranging from small to over 10 kg

MIM:

- Fast initial molding, but long overall process due to post-processing

- Best for small, complex, high-precision parts where cycle time is less critical

Key Processing Insights

Die casting wins if your top priority is fast cycle times and high part quantities. MIM is chosen for complex, small-scale, high-tolerance parts. You accept slower production to get precision and design flexibility.

Summary Table: Processing Speed Comparison

| Process | Cycle Time | Typical Throughput | Best For |

|---|---|---|---|

| Die Casting | 1–30 sec/part | 1,000–1,200 parts/hour | High-volume, simple to large parts |

| MIM | Slower overall | Thousands/day | Small, complex, high-precision parts |

Key data point:

If your goal is fast, repeated production of simple metal parts, I suggest die casting. It’s the industry standard for speed. MIM supports more complex designs. You trade slower post-molding throughput for better precision and flexibility.

Key Advantages and Disadvantages of Metal Injection Molding (MIM) and Die Casting

I recommend comparing metal injection molding (MIM) and die casting based on their strengths and weaknesses. This helps you pick the right process. Below is a breakdown based on real production data, pricing, and applications.

Key Advantages of Metal Injection Molding (MIM)

-

Produces Intricate, Small Parts: MIM makes components with complex shapes and fine details. Die casting cannot match this. You can create features as fine as <2 mm. Wall thicknesses under 0.5 mm are possible.

-

Wide Range of Material Options: MIM handles ferrous and non-ferrous metals. These include stainless steel, tool steel, cobalt, tungsten, nickel alloys, and titanium. This flexibility helps meet tough needs in medical and electronics fields.

-

Superior Surface Finish and Tolerance: As-molded surfaces can reach a smoothness of Ra 1 μm. You get dimensional accuracy down to ±0.05 mm.

-

Excellent Mechanical Properties: Parts reach 95–99% density compared to wrought metals. This gives you high strength, wear resistance, and corrosion resistance.

-

Optimized for Small, High-Volume Runs: I suggest MIM for production volumes above 10,000 units. It works best for precise, small parts (<50g, ideally 15–20g).

-

Typical Applications: MIM produces complex medical device pieces, micro-gears, stainless-steel watch cases, electronic connectors, and precision firearm components.

Primary Disadvantages of Metal Injection Molding (MIM)

-

Higher Cost for Tooling and Processing:

Tooling cost: $1,400–$2,800. MIM uses multi-step post-processing (debinding and sintering). This adds time and labor costs compared to die casting. -

Production Cycle Time: Initial molding is fast. But the total cycle (including debinding and sintering) takes 25–30 days per full batch.

-

Part Size Limitations: MIM is cost-effective for parts up to 50g. Larger parts are rare and less economical.

-

Shorter Mold Life: Molds last 150,000–300,000 cycles. This is much less than die casting molds.

Key Advantages of Die Casting

-

High Production Speed and Output:

Cycle times: Just 1–30 seconds per part. This enables rapid mass production (up to 1,200 parts/hour for small components). -

Long Mold Life, Lower Cost at Scale: Molds cost $1,200–$4,200. They can last for up to 1 million shots. This delivers excellent value for large-scale manufacturing.

-

Large Part Capability: Die casting produces parts weighing from 30g to over 10kg. This includes automotive housings, lighting fixtures, and appliance components.

-

Dense, Consistent Parts: Output is 100% dense. This delivers reliable strength and structure for large items.

-

Cost Advantage in High-Volume, Simple Parts: Up to 30% cheaper per unit for large, high-volume, or less-complex parts.

Primary Disadvantages of Die Casting

-

Material Limitations: Die casting works best for non-ferrous metals (aluminum, zinc, magnesium, copper). Using ferrous metals causes rapid mold wear.

-

Porosity Risks: High-pressure injection can trap gases. This causes internal porosity. It can affect strength and surface quality.

-

Surface Quality: Surface roughness is around Ra 1.6–3.2 μm. You often need post-processing for aesthetic or assembly uses.

-

Lower Precision for Fine Features: Die casting is not suitable for parts with thin walls (<0.5 mm) or detailed geometries.

-

Upfront Investment for Complex Tools: Complex, long-life molds cost up to $4,200 or more.

Quick Comparison Table

| Factor | Metal Injection Molding (MIM) | Die Casting |

|---|---|---|

| Typical Tooling Cost | $1,400–$2,800 | $1,200–$4,200 |

| Mold Life | 150,000–300,000 parts | Up to 1,000,000 parts |

| Density | 95–99% | 100% |

| Part Complexity | Very high; intricate, tiny features | Moderate; larger, less complex shapes |

| Minimum Feature/Wall | <2 mm / <0.5 mm | >2 mm / >0.5 mm (most cases) |

| Surface Finish | As smooth as Ra 1 μm | Ra 1.6–3.2 μm |

| Application Examples | Medical/biotech, watches, sensors, electronics, firearms | Automotive, lighting, furniture, appliances |

| Volume Suitability | High (10,000+ small parts) | Medium to very high; large/medium parts |

Summary List of Key Differences

-

MIM is best for small, complex, tight-tolerance parts with premium materials. You will pay higher costs. Mold life is shorter.

-

Die Casting excels at making large, simple shapes at very high speed and volume. It offers cost advantages at scale. But material options and feature detail are limited.

Based on my experience, I recommend MIM for precision work. I suggest die casting for larger, simpler parts that need speed and volume.