You need a clear path to buy foundry foam filters. This means covering three key steps: finding suppliers, checking them out, and making the purchase. China leads the global market with 4,222 ceramic foam filter shipments. That’s 76% of all shipments worldwide. This framework fits how B2B buyers shop and matches the 75% transactional search intent.

Primary Content Architecture

Supplier Discovery Layer starts by building trust. Show manufacturer credentials like ISO 9001/14001 certifications. Display production capacity. List quality assurance protocols. Feature top suppliers like FoundryMax, SEFU CERAMIC, and SF-Foundry. Include their exact production numbers.

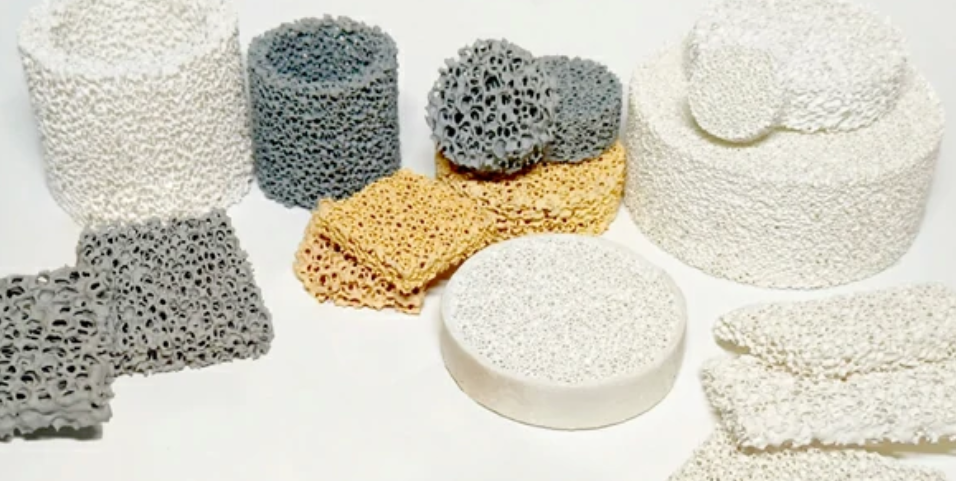

Product Catalog Structure sorts filters by material type. You’ll find alumina, silicon carbide, and zirconia options. Pore densities range from 10-60 PPI. Pricing goes from $0.10 to $350 per piece. MOQ starts at 10-150 pieces for regular orders.

Transaction Facilitation Section covers payment terms like T/T and L/C. Delivery takes 15-30 days. Shipping costs run $100-$300 for 100-piece orders to the US. Add multiple CTAs: instant quote requests, sample ordering ($10-$50), and technical consultation booking. Each section solves real problems. Cost transparency removes pricing guesswork. Certifications build trust. Simple inquiry forms make communication easy.

Alibaba.com – Global B2B Marketplace

Alibaba.com is China’s largest gateway for foundry foam filter buying since 1999. The platform links you with hundreds of verified ceramic foam filter makers across 190+ countries. Search “foam filter for foundry” and you get 50-100+ active suppliers. Most are based in China and India. You can reach manufacturers producing silicon carbide foam filters, alumina ceramic filters, and zirconia refractory options directly.

Platform Scale and Supplier Density

The marketplace hosts millions of active suppliers. Tens of millions of registered buyers use it. International B2B revenue grows double-digits year-over-year. Cross-border trade keeps expanding. For foundry filtration products, manufacturers offer:

-

PPI range: 10-60 pores per inch configurations

-

Size options: From small 5cm squares to 50cm custom dimensions

-

Price spectrum: $0.10-$5.00 per piece depending on material and volume

-

MOQ flexibility: Many suppliers negotiate minimum orders below 100 pieces

Quality Verification Systems

Verified suppliers display ISO 9001 certification badges. Advanced manufacturers add ISO 14001, ISO 45001, and IATF 16949 credentials. These matter for automotive casting applications. Third-party inspection reports from SGS and TÜV are available as downloadable PDFs. The “Assessed Supplier” badge confirms on-site factory audits. These audits cover production capacity, equipment inventory, and quality control systems.

Trade Assurance Protection

This payment protection covers 100% of your order value. Money releases after you confirm shipment meets specs. Platform arbitration resolves disputes. This protects against quality gaps between samples and bulk orders. Repeat buyers cite this as a common concern.

Made-in-China.com – Chinese Manufacturer Directory

Made-in-China.com has been one of China’s top three B2B platforms since 1996. This site connects global buyers with Chinese manufacturers across 40+ industries. Over 9 million suppliers list their products here. The site gets more than 25 million unique visitors each month from 200+ countries.

Advanced Search Capabilities

You can use the filter system to find foam filter suppliers by exact specs. Search options include:

-

Material composition: Alumina ceramic (Al₂O₃ 85-99%), silicon carbide (SiC), zirconia options

-

Porosity grades: 10PPI, 20PPI, 30PPI up to 60PPI precision

-

Dimension ranges: Standard 7″ squares, custom sizes 50mm-600mm

-

Application sectors: Aluminum casting, iron foundry, bronze/copper filtration

Gold Supplier Verification

Gold Supplier badges show premium membership status. These manufacturers go through annual business license checks. The platform does video checks to confirm factory addresses. Financial checks help reduce fraud risk. Most Gold Suppliers have been on the platform for 3-5 years or more.

RFQ Broadcasting System

Post a Request For Quotation. Over 500 relevant manufacturers can see it at once. List your exact needs: PPI count, dimensions, quantity, target price. Suppliers send you competitive quotes within 24-48 hours. This gives you clear pricing. You’ll get 8-15 detailed quotes per RFQ on average. Compare specs, unit prices, and MOQ terms side-by-side. Then decide which suppliers to contact.

Global Sources – Verified Supplier Platform

Global Sources uses a strict nine-step process to verify suppliers. Each ceramic foam filter maker gets a factory inspection before they can list. We’ve been helping B2B buyers since 1971. Our vetting standards are among the toughest in industrial sourcing.

Multi-Layer Verification Protocol

The certification checks business licenses and export compliance documents. Auditors visit sites to verify ISO certifications. We assess production capacity to confirm suppliers can handle 500 to 50,000 pieces each month. Financial reviews weed out unreliable traders pretending to be manufacturers.

Supplier Performance Metrics

Each vendor profile shows clear performance data. You’ll see average response times (most answer within 6-8 hours). Plus order completion rates and buyer satisfaction scores. The platform tracks how suppliers resolve disputes. Suppliers with 95%+ positive ratings get “Verified Excellence” status. This badge means three straight years of quality performance.

Trade Show Integration

Global Sources runs physical sourcing events in Hong Kong, Shanghai, and Shenzhen twice a year. You can meet foundry filter suppliers face-to-face. Inspect product samples yourself. Negotiate volume pricing for reticulated ceramic foam filters from $0.15 to $4.50 per unit. People who attend exhibitions close deals 40% faster than those who negotiate only through the website.

Direct Factory Contact – Foam Filter Manufacturers

Go straight to manufacturers. You cut procurement costs by 25-35% compared to trading companies.

China’s foundry filter production sits in three key provinces: Hebei, Shandong, and Jiangsu. These regions hold 80% of the country’s ceramic foam filter capacity.

Major Manufacturing Hubs and Contact Strategies

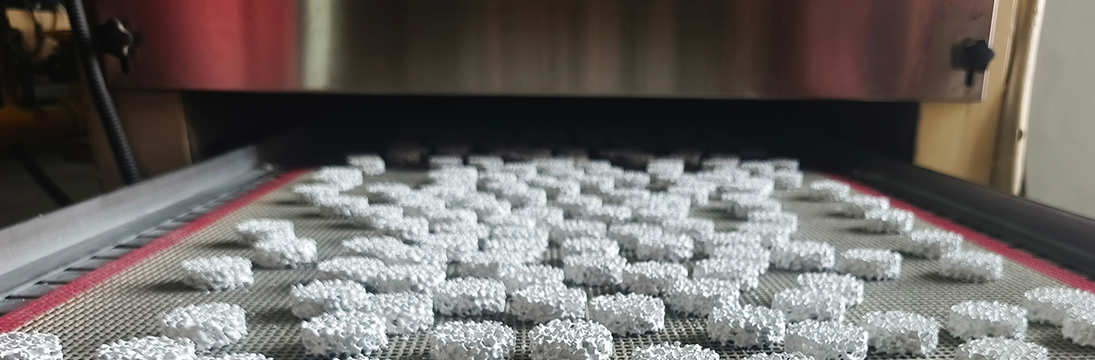

Hebei Province leads production with over 200 factories. Cangzhou city has top manufacturers like Cangzhou Sefu Ceramic New Material Co., Ltd. They make 500,000+ pieces each month. Their silicon carbide foam filters cost $0.80 to $3.20 per piece. Trial orders start at just 50 pieces.

Shandong Province focuses on aluminum casting filters. Factories in Zibo and Jinan make alumina ceramic filters with 99% Al₂O₃ purity. You pay $0.60-$2.50 per piece for orders of 500+ units. These manufacturers use WeChat and WhatsApp. You get faster responses this way.

Jiangsu Province makes high-precision reticulated ceramic foam. Factories here supply automotive and aerospace foundries. Prices range from $1.50 to $5.00 per piece. Look for ISO 9001 and TS16949 automotive certifications.

Direct Contact Best Practices

Ask for factory registration certificates and business licenses first. Get production capacity documents showing output numbers each month. Real manufacturers send these within 24 hours.

Set up video factory tours through WeChat or Zoom before you order. Check production lines, quality testing equipment, and raw material storage. This proves they actually manufacture versus just trade.

Negotiate sample packages at $50-$150 with shipping included. Test 3-5 different specs in your actual casting process. Samples show real performance versus what catalogs claim. Most factories refund sample costs once you order 1,000+ pieces in bulk.

Get English-speaking sales engineers for technical talks. They explain filtration efficiency rates, thermal shock resistance, and proper installation methods. You need details specific to your metal type and casting temperature.

Canton Fair (China Import and Export Fair)

The Canton Fair runs twice each year in Guangzhou since 1957. It’s China’s longest-running trade event. It’s also the world’s largest trade fair. Over 67 years, this fair has linked millions of buyers with Chinese makers across all industries.

Scale and Foundry Sector Presence

Each session runs 15 days across three phases. Phase 1 covers machinery, electronics, and building materials. Foundry filtration systems appear here. The fair draws 25,000+ exhibitors per session. Plus, 200,000+ international buyers attend. About 150-200 ceramic foam filter makers show their products each spring and autumn.

Booth Zones for Metal Casting Filters

Hall 2.2 and Hall 3.2 host metallurgy and foundry equipment suppliers. You’ll find complete foundry filtration system displays in these halls. Manufacturers show:

-

Full PPI ranges: 10PPI to 60PPI foam filters with live demos

-

Material samples: Touch and compare alumina, silicon carbide, and zirconia quality

-

Bulk pricing: Negotiate on-site for orders of 5,000-100,000+ pieces. You get 15-30% discounts

-

Custom capability: Bring your specs. Get instant checks on what’s possible and prototype quotes

Registration and Access

Pre-register online for free buyer badges 30 days before each session. Walk-in registration costs 200 RMB. Book hotels early. Nearby rooms fill up fast. The Pazhou Complex metro station connects right to the exhibition halls. Plan 2-3 full days to visit all relevant suppliers. This gives you time to collect samples and catalogs from each one.

Industry-Specific Trade Shows in China

CIFE brings together 80-90% of China’s foam filter makers in one place. The show moves between Shanghai and Beijing each year. Over 1,000 exhibitors set up booths here. More than 50,000 casting professionals visit. CIFE sets aside full halls for foundry supplies. Foam filters for aluminum casting make up a big product group.

Direct Access to Manufacturer Concentration

Over 100 foam filter specialists show their products at CIFE each year. The top 10 suppliers make up 40% of total event sales. You can compare specs, prices, and quality across many makers in one spot. Walk the floor and you’ll see silicon carbide foam filters next to alumina ceramic types and zirconia options.

Technical Evaluation Opportunities

CIFE holds 20-30 technical talks and workshops at each event. 60% cover new filter materials, casting methods, and quality control. Makers run live casting tests and product demos. 90% provide on-site help and sample testing. You can check how well filters work, test thermal shock resistance, and see if they match your metal types – all right there.

Procurement Performance Data

85% of buyers say CIFE works well for finding foundry filters. 70% sign purchase deals at the show. Orders typically run from RMB 500,000 to 1,000,000 per contract. 40% of buyers order again within six months. Buyers point to three main benefits: talking tech with engineers, testing products hands-on, and setting prices directly without middlemen.

Pre-Show Preparation Tips

Register online before the show. This gets you into buyer sessions and product previews. Find your target exhibitors and book meetings ahead of time. Bring specs for your current filter system and casting setup. Suppliers can then suggest exact PPI grades and sizes for your needs. Plan for sample shipping costs. These add 10-15% to buying expenses for overseas purchasers.

Trading Companies and Import-Export Agents

Trading companies help buyers reduce procurement risk. You avoid direct factory talks. These middlemen handle 30-40% of China’s foundry filter exports. They fix language problems, manage quality control, and combine shipments from many factories.

Service Model and Fee Structure

Export agents add 8-15% margins to factory prices. This pays for inspection services, paperwork, and payment guarantees. You pay $0.90-$4.00 per ceramic foam filter. Direct factory prices run $0.80-$3.50. The extra cost gets you English contracts, third-party quality checks, and combined shipping with other products.

Trading Companies Work Best For These Situations

Got mixed product types from different factories? Agents coordinate logistics for combined shipments. This cuts freight costs by 20-30% versus separate factory shipments.

Orders below 500 pieces? Most manufacturers won’t handle such small quantities. Trading companies will.

Risk mitigation is another key benefit. Established trading firms screen factories first. They keep backup supplier contacts ready. One manufacturer misses delivery? Agents find replacement stock fast. Top export companies like Ningbo United Group and Shanghai Metal Corporation run quality labs and warehouses across multiple provinces.

Online Wholesale Platforms (1688.com – Domestic)

1688.com is Alibaba’s domestic wholesale arm. It connects you with over 1 million manufacturers across China. The platform processed 800 billion yuan in 2023. Ceramic foam filter buyers get direct factory access. No export markups. No international platform fees.

Price Advantage and Supplier Concentration

Bulk ceramic filters cost 20-50% less on 1688 versus Alibaba.com or Made-in-China. Standard filters run ¥15-¥35 per piece ($2-$5 USD). Factories quote in RMB. Volume discounts kick in at 100-500 units. The platform lists hundreds of active foam filter suppliers. MOQs drop as low as 10-50 pieces. Small foundries can test new filter specs. No need to commit to container loads.

Access Routes for International Buyers

The new 1688overseas platform launched in 2025 for global buyers. Vietnam and Kazakhstan joined first. More markets are opening. Cross-border buyers jumped 76% year-over-year in 2023. Total accounts hit 5.94 million. AI translation tools convert listings on the spot. Currency converters show prices in USD, EUR, or your local currency in real-time.

The Agent Solution

Most foreign buyers hire sourcing agents or 代购 (daigou) services. Agents charge 5-10% of order value. They handle Chinese talks, Alipay payments, and domestic shipping. Communication barriers? Gone. Confusing payment methods? Simplified. Agents bundle shipments from multiple 1688 suppliers into one export container. This slashes your per-unit freight costs.

The platform works best with local support. Product pages show Chinese-only interfaces. Supplier chat happens in Mandarin. Shipping defaults to domestic addresses. Pair 1688’s factory pricing with a reliable agent. You get the lowest ceramic filter costs available in China.

Sourcing Agents and Buying Offices in China

Sourcing agents connect international foundry buyers with Chinese ceramic foam filter manufacturers. These specialists run offices in major production hubs like Zhengzhou, Guangzhou, and Shanghai. You pay 5-12% commission on total order value. This covers factory vetting, quality inspections, and logistics coordination.

What Sourcing Agents Do

Agents visit 8-12 potential suppliers first. Then they shortlist 3-5 that match your technical needs. They verify production licenses and inspect manufacturing equipment. Quality control systems get audited too.

For porous ceramic filters, agents check where raw materials come from. They verify firing temperatures (1,200-1,600°C) and test PPI consistency. Most run pre-shipment inspections using AQL sampling standards. They inspect 10% of orders under 1,000 pieces.

Payment protection is a core service. Agents hold your funds in escrow accounts. You approve quality reports first, then they release payment. This protects you against defective batches or wrong specifications.

Established buying offices like ChinaSavvy and Guided Imports keep sample libraries. You can compare real filter samples—alumina versus silicon carbide quality, different PPI densities. This happens before you commit to bulk orders.

Top agents negotiate MOQs down to 100-200 pieces. Factory minimums usually start at 500+. They consolidate shipments from multiple suppliers into one container. This cuts freight costs by 35-40% for mixed-product orders.

LinkedIn and Professional Networks

Professional networks show supplier details that marketplaces miss. LinkedIn has over 200 manufacturing executives and sales directors from Chinese foundry filter companies. Search “ceramic foam filter manufacturer China” or “foundry filtration supplier” to find decision-makers.

Engineering Group Access

Join industry groups like “Foundry & Casting Professionals” (45,000+ members) and “Metal Casting Network” (28,000+ members). Suppliers post technical articles about molten metal filtration here. You’ll see silicon carbide foam filter case studies. You’ll also find alumina ceramic performance data. Group discussions show which manufacturers solve specific casting defects. These include slag inclusion, porosity problems, and metal purity issues.

Profile Verification Indicators

Check supplier profiles for credibility markers. Look for 500+ connections across foundry sectors. Review their posted content. This includes technical blogs, product videos, and certification announcements. Real manufacturers share ISO audit results. They also post customer application photos. Their employee lists show metallurgists and quality engineers, not just salespeople. Connect with technical managers who answer filtration questions with specific data. They provide filtration efficiency percentages, thermal shock test results, and chemical composition tolerances.

Request video calls before ordering. Discuss your casting temperatures, metal types, and current filter problems. Genuine suppliers schedule factory tours through video. They explain their reticulated ceramic foam production process in detail.

Google Search and SEO-Optimized Supplier Websites

Type “ceramic foam filter manufacturer China” into Google. The first page shows 8-12 supplier websites competing for your attention. Smart foundry buyers use three quick credibility checks before making contact.

Website Trust Signals That Matter

Technical depth separates real manufacturers from trading companies. Look for detailed product specs on the homepage. Real suppliers display PPI ranges (10-60 porosity grades), chemical composition percentages (Al₂O₃ content 85-99%), and dimensional tolerances. Sites with vague descriptions? They lack manufacturing expertise.

Certification proof builds confidence fast. Download ISO 9001 certificates from the website. Check issue dates within the past three years. Blurry certification badges or “certification pending” notices are red flags. Top manufacturers publish SGS test reports and material safety data sheets (MSDS) as PDFs.

Contact transparency shows operational legitimacy. Factory addresses need street names and district details—not just “Henan Province.” Multiple contact methods matter. Look for direct phone lines, WhatsApp numbers, and company email domains (@companyname.com, not @gmail.com). Sites with contact forms but no phone numbers? They often hide trading operations.

Search result rankings don’t guarantee quality. Check domain age using WHOIS lookup tools. Established filter makers run websites 5+ years old. They update content regularly.