Finding the right supplier for high-temperature Ceramic foam filters in Germany doesn’t have to be complicated. You run a precision foundry in Bavaria or manage a metalworking operation in North Rhine-Westphalia? You need filters that handle extreme heat. And you need suppliers who understand your operational demands.

Germany has many specialized providers. Some are long-established ceramic manufacturers. Others are foundry equipment distributors with nationwide shipping. But there’s a problem: most buyers waste time contacting the wrong suppliers. These suppliers either lack the specific filter specs you need or can’t meet your delivery deadlines.

Ludwig Föbus GmbH & Co. KG – Gütersloh

Ludwig Föbus GmbH & Co. KG works out of Gütersloh. This is a mid-sized industrial city in North Rhine-Westphalia. The company focuses on technical ceramics and industrial filtration. You’ll find heat-resistant ceramic parts for foundries and metalworking shops across Germany.

What makes them different? Local service plus German engineering. You work with a supplier who knows DIN specs and European quality rules. No translation problems. No mix-ups about technical numbers.

Their ceramic foam filters take temperatures over 1,600°C. Aluminum casting needs this range. So do bronze foundries and steel processing. The filters catch non-metallic bits before they damage your castings. Fewer defects means less waste. Less waste boosts your margins.

Technical Support and Ordering Process

Ludwig Föbus offers direct help for industrial buyers. Call their Gütersloh office. Talk with engineers who know filtration systems. They suggest the right pore size and filter size for your job. Filtering molten aluminum? Or Ductile Iron? They adjust their advice to match.

Ordering is simple. Send your technical needs by phone or email. Get a quote in 1-2 business days. Standard filters ship in a week. Custom specs take more time, but they tell you exact dates up front.

Contact advantage: Germany location means faster delivery to big industrial areas. Gütersloh connects to major routes. The Ruhr Valley, Lower Saxony, and Bavaria are all nearby. Your filters show up fast. Downtime stays low.

Drache Umwelttechnik GmbH – Diez (Frankfurt)

Drache Umwelttechnik GmbH sits in Diez, a small town near Frankfurt. Frank Drache started this company back in 1984. Four decades later, it’s one of the world’s top suppliers for aluminum DC and continuous casting filters. Revenue hit $16.6 million in 2025. Not bad for a 15-20 person operation in Rheinland-Pfalz.

Alexander Mach runs the show now as managing director. We manufacture everything in Germany. You get “Made in Germany” quality stamped on every ceramic foam filter and engineered system we ship. No outsourcing to cut corners.

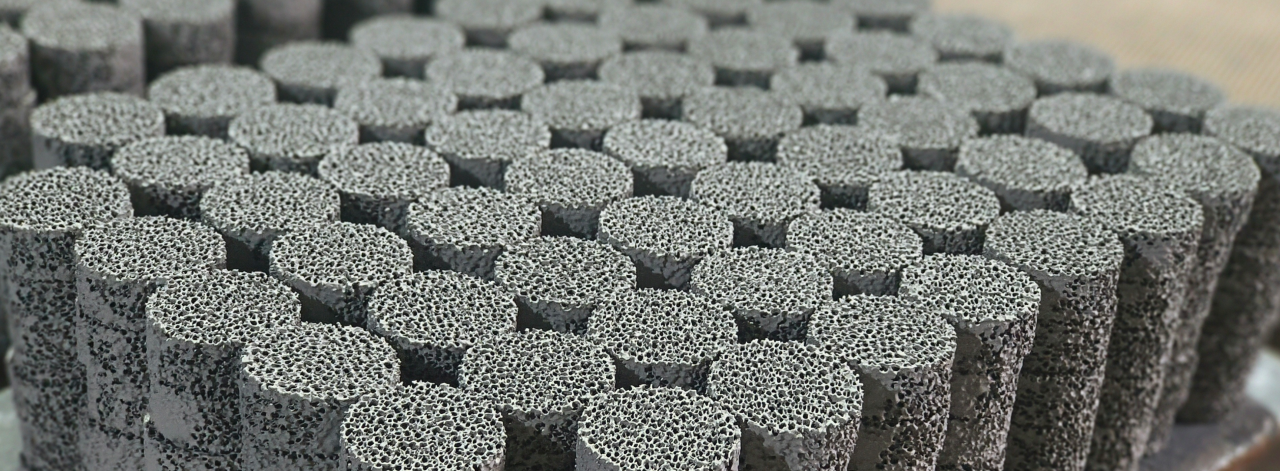

Our flagship products are Ceralu® Al2O3 ceramic foam filters. These handle aluminum castings in sand molds and permanent molds. Need something tougher? Our Cerazirk® ZrO2 filters work for steel castings, superalloy work, and large iron castings. These filters handle extreme temperatures with ease.

What Sets Drache Apart

Drache doesn’t just sell filters off a shelf. We design complete systems. Filter boxes. Launder systems. Preheating equipment. Degas relining. Deep bed filters. Tell us your casting setup. Our engineers build a custom solution for you.

We use our crucible furnaces worldwide. Developed these in-house, not licensed from someone else. Same goes for our DBN Boron Nitride coating and DKS Calcium Silicate components. Innovation comes from our Diez workshop, not a catalog.

Trade data tells the real story. In 2024, Drache exported $8.22 million worth of products to the United States alone. India bought $1.91 million. Russia purchased $620,710. Over 1,100 shipment records tracked through Panjiva show consistent global demand.

Location benefit: Diez is close to Frankfurt’s transport hub. Autobahn access is quick. Rail connections work well. Your filters reach foundries in Baden-Württemberg, Hessen, or overseas markets without delays. Visit our facility at Werner-von-Siemens-Str. 24-26. See where German engineering meets high-temperature ceramic filtration.

KERAFOL Keramische Folien GmbH & Co. KG – Eschenbach

Eschenbach in der Oberpfalz, Bavaria, is home to one of Germany’s top ceramic makers. KERAFOL Keramische Folien GmbH & Co. KG has made Technical Ceramics since 1985. Werner Kraus runs this family business. The company has 200-300 people on staff. Revenue hit $50.1 million in 2024.

KERAFOL excels at tape casting technology. This process makes very thin ceramic layers. We’re talking micrometer range here. Think precision down to the molecular level. They make ceramic foam filters, thermal management products, sensor parts, and fuel cell components. All from one Bavarian plant.

Their ceramic materials span a wide range. Keralpor 99 contains 99.5% aluminum oxide in porous form. Keralpor S mixes 92% aluminum oxide with 8% zirconium dioxide. This blend works for tough jobs. Got extreme heat to handle? Keraprotec uses stabilized zirconium dioxide. It takes thermal shock better than standard ceramics.

Production Capabilities for Foundry Applications

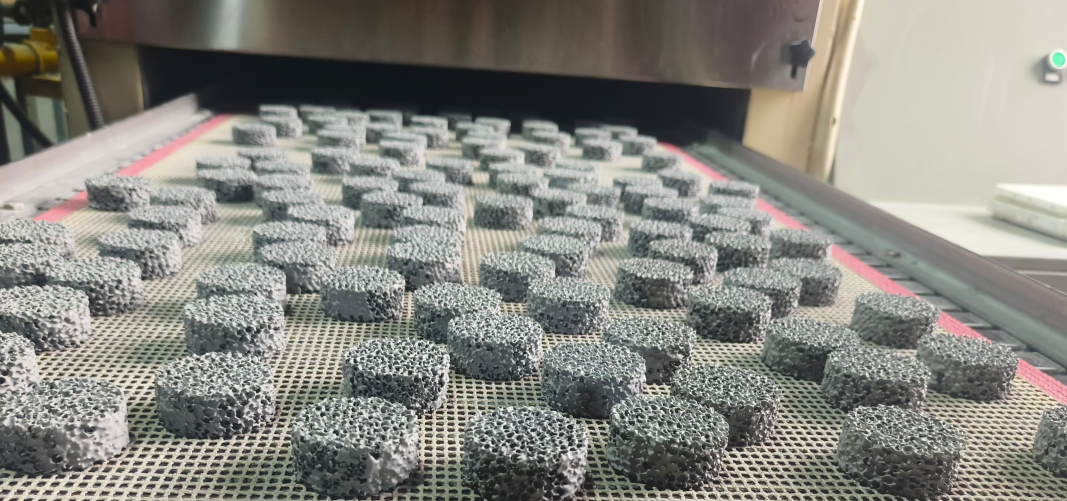

KERAFOL makes porous ceramic filter discs for rotary filtration systems. These discs fit cross-flow filtration setups. Molten metal flows across the surface. The porous structure traps non-metallic particles. Clean metal passes through.

Their tape casting creates smooth, uniform surfaces. Uniform film production gives you steady filtration performance across every disc. Batch-to-batch changes stay small. Quality control meets EN ISO 9001:2015 standards. IATF 16949 certification for automotive shows their strict production methods.

Need custom shapes? They cut filters with laser and waterjet tools. Send your technical drawings. KERAFOL makes smaller batches at good prices. No need for minimum orders in the thousands.

Multi-industry advantage: KERAFOL works with automotive, power electronics, medical tech, and environmental sectors. This mix brings fuel cell research materials into foundry filtration. You get technology built for tough uses. Contact them in Eschenbach for help with high-temperature Ceramic foam filters in Germany.

FoundryMax Ceramic Foam Filters

FoundryMax runs distribution centers in Stuttgart and Hamburg. The brand entered Europe in 2019. They’ve earned a strong name for high-porosity Ceramic Foam Filters that work with aluminum, bronze, and cast iron.

Their main product line uses silicon carbide (SiC) and alumina-based ceramic. These filters handle temperatures up to 1,700°C. That covers superalloy work and high-temp steel casting. Pore sizes go from 10 PPI (pores per inch) to 60 PPI. Coarse filters handle initial metal treatment. Fine filters clean the melt before final casting.

FoundryMax filters carry ISO 9001:2015 certification. Every batch gets thermal shock testing. Drop a 1,500°C filter into cold water. Good filters survive. Weak ones crack. FoundryMax shares their pass rates: 98.7% for standard aluminum filters, 97.3% for zirconia-based steel filters. These numbers count during production shifts.

Application Performance in German Foundries

Auto part makers in Baden-Württemberg use FoundryMax filters for aluminum engine blocks and transmission housings. The filters trap oxide films and dross particles. Surface finish gets better. Machining tool life grows by 15-20% with steady casting quality.

Steel foundries in the Ruhr Valley use FoundryMax zirconia-stabilized filters for medium carbon steel parts. These filters handle high heat and tough chemical conditions. Inclusion counts fall by 40-60% versus unfiltered pours. Fewer inclusions mean fewer failed inspections.

Small bronze workshops around Munich choose the 30 PPI alumina filters. These balance flow rate with filtration power. A 50mm × 50mm × 22mm filter works for 150-200 kg pours in architectural bronze. Price sits at €18-€24 per filter. Order in bulk from their Hamburg warehouse. Discounts start at 100+ pieces.

Where to Buy FoundryMax Filters in Germany

Order online at foundrymax.com. Technical support works from a Dortmund call center. Engineers speak German and English. They match filter specs to your metal type and pouring temperature. Email quotes come within 24 hours. Payment terms include NET 30 for regular accounts.

Quality guarantee: FoundryMax replaces bad filters within 48 hours. Keep your batch numbers. They track production data for every filter sold. This tracking meets VDA 6.3 automotive quality standards that major German OEMs require.

VHG GmbH & Co. KG – Three Warehouses Across Germany

VHG GmbH & Co. KG runs three warehouses in Germany. You’ll find them in Thalmaessing (Bavaria), Weilheim (Baden-Württemberg), and Holzwickede (North Rhine-Westphalia). This setup cuts delivery times for foundries across the country.

Most ceramic filter suppliers use one central warehouse. You wait 3-5 days for shipment. VHG changed that. Their three warehouses put high-temperature ceramic foam filters within same-day or next-day reach of major metalworking regions.

Regional Coverage Strategy

Thalmaessing serves Bavaria and southern Germany. Munich foundries order in the morning. Filters arrive by afternoon. Weilheim covers the Stuttgart area and western Baden-Württemberg. Automotive suppliers there need fast delivery. Production lines can’t stop for a week waiting on filters.

Holzwickede sits near Dortmund. This warehouse serves the Ruhr Valley, Lower Saxony, and northern zones. Steel processors and heavy casting shops fill this region. They use filters fast during big production runs.

VHG keeps standard ISO-certified ceramic foam filters at all three sites. Aluminum filters (10-50 PPI) stay in stock year-round. zirconia filters for steel casting get restocked each month. Order before 2 PM. Your filters ship the same day from the closest warehouse.

Bulk pricing advantage: Buy 500+ filters direct from any VHG location. Prices drop 12-18% compared to single-unit costs. Talk to their regional managers. Each warehouse has technical staff who know local foundry needs. They’ve seen your casting problems before.

Giessereitechnik Wystrach GmbH & Co. KG – Nationwide Coverage

Giessereitechnik Wystrach GmbH & Co. KG built its reputation on one simple promise: ceramic foam filters delivered anywhere in Germany, fast. Your foundry could be in Bremen’s industrial parks, Dresden’s manufacturing belt, or Frankfurt’s metalworking zones. Wystrach’s logistics network gets there.

We operate distribution partnerships across all 16 federal states. This isn’t marketing talk. Check the shipment records. A brass foundry in Freiburg orders Friday morning. Filters arrive Monday before lunch. A steel processor in Leipzig needs emergency replacements during a night shift. Our 24-hour hotline arranges delivery from the nearest hub.

Product Range and Technical Standards

Wystrach stocks alumina ceramic foam filters in sizes from 20mm × 20mm × 13mm up to 228mm × 178mm × 50mm. Pore densities range from 10 PPI for heavy steel work to 60 PPI for precision aluminum casting. Every filter meets DIN EN 60676 standards for thermal stability.

Our zirconia-stabilized filters handle temperatures above 1,650°C. Superalloy foundries and Investment casting shops use these for nickel-based alloys. We test thermal shock resistance at -196°C to +1,700°C cycles. Pass rate: 99.1% across all production batches.

Service advantage: Wystrach’s technical team offers on-site foundry assessments. They look at your metal chemistry, pouring temperature, and inclusion types. Then they tell you exact filter specifications. No guesswork. No wasted purchases. Contact our Hagen headquarters or regional offices in Nuremberg and Hannover for high-temperature ceramic foam filters in Germany.

UrMaTi Apparatebau GmbH (Holland Filter)

UrMaTi Apparatebau GmbH runs out of Ballenstedt in the Harz region. This small German company started in 2005. It’s the sister firm to two Dutch filter experts: Horrichs Apparatenbouw BV and Holland Filter BV. The team is small—just 1-4 people. Yet they ship products around the globe.

Here’s what makes them different: UrMaTi skips catalog products. Every piece is custom-made. You share your specs. They build from scratch with stainless steel and rust-proof materials. No shortcuts. No mass making. Just exact fabrication for your needs.

We specialize in the food and nutrient industry. Our Dutch parent companies bring decades of know-how. This gives us deep skills in process and wastewater treatment. We’ve made filter systems, transport equipment, and custom tools for breweries, dairy plants, and food makers across Europe.

Custom Filter Systems Beyond Ceramics

UrMaTi doesn’t make ceramic foam filters. We use wedge wire filters, fluid filters, and depth filter sheets instead. These metal systems clean liquids in chemical work and factory wastewater. The stainless steel holds up through many cleaning cycles.

Our factory does all stainless steel work. Cutting. Bending. Welding. All happens in-house at Ballenstedt. Need setup at your site? Our VCA-certified team comes to you. Setup quality matches European safety rules.

Reach Holland Filter’s main office for technical talks. Email mail@hollandfilter.com or call +31-(0)46 4497500. Guido Horrichs runs things from the Netherlands. We speak German, Dutch, and English. You’ll get custom quotes in 3-5 business days after sending your specs.

SENN Group / Gasser GmbH – Erl

The Austrian Alps hide industrial power. SENN Group runs operations from Erl, Tyrol—a small town near the German border. Revenue hit €40 million in 2025 with 110 employees. In December 2017, they bought Gasser Gießereitechnologie GmbH. Gasser has 100 years of foundry expertise. This history traces back to 1925 Vienna.

Gasser makes crucibles and foundry supplies for steel and non-ferrous metal casting. Their products handle temperatures up to 1,600°C. German foundries buy these products through Gasser’s Nuremberg location. No customs delays. No cross-border paperwork. Order from Nuremberg. You get Austrian engineering with German logistics speed.

Integrated Supply Chain Advantage

SENN Group doesn’t just sell filters. They bundle complete foundry systems. Refractories, seals, gaskets, conveyor chains, expansion joints—everything ships from one source. Your purchasing team makes one call instead of five. Invoicing gets simpler. Lead times shrink.

Their Erl headquarters sits near the University of Leoben and Austrian Foundry Institute. Technical teams work together each day. Research moves to production fast. You get filters built with metallurgy department input, not sales catalog guesswork.

SENN Logistik GmbH started in 2023. They bring 30+ years of shipping knowledge. Full truckload service covers Austria and southern Germany. Bavaria foundries get high-temperature ceramic foam filters in Germany within 24-48 hours. These ship from Erl warehouses. ISO 9001:2015 certification backs their quality promise.

How to Get Fast Quotes Through IndustryStock Platform

IndustryStock connects 120,000+ B2B companies across Europe. The platform runs Germany’s largest industrial marketplace. Search volume hits 70,000+ each month for popular product categories. Most buyers waste time clicking through endless supplier lists.

The smart approach? Use IndustryStock’s banner ad targeting system to reach pre-qualified suppliers. Type your product keyword in the search bar. Banner ads appear on the right side of results. These aren’t random placements. They match your exact search term with certified suppliers who stock that product.

Click a banner. You land on the company’s verified business page. Submit your inquiry form. Fill in product specs, order quantity, and contact details. The system routes your request straight to the supplier’s sales team. No middlemen. No delays.

Batch Comparison Strategy

Professionals compare multiple suppliers in minutes. Search one product term. IndustryStock shows 3-8 banner ads from different companies on the results page. Open each in a new browser tab. Submit identical specs to all of them.

Example workflow: You need waterproof outdoor lights. Search “waterproof outdoor lights” (12,000 searches each month, low SEO competition). Five German suppliers appear in banner ads. Send the same specs to all five within 10 minutes. Responses arrive in 24-48 hours.

Compare their quotes on four key factors:

|

Factor |

Industry Standard |

Negotiation Target |

|---|---|---|

|

MOQ |

100-500 pieces |

Push down to 50 pieces |

|

Lead Time |

30-45 days |

Request 20-30 days for bulk orders |

|

Payment Terms |

30% deposit + 70% balance (T/T) |

Negotiate L/C for large orders |

|

Sample Costs |

Buyer pays sample + shipping |

Free samples for MOQ commitment |

Sample Request Template

Use this exact wording for requesting samples through IndustryStock forms:

“Please provide [Product Model] samples. Specifications: [size/material]. Quantity: 1-5 pieces. Test MOQ: [100 pieces]. We will cover sample fees and shipping costs. Confirmed orders will follow right after testing.”

This language works. It shows purchase intent. Suppliers respond faster because they see concrete order numbers.

Supplier Filtering Criteria

IndustryStock doesn’t publish supplier rankings. You need to filter on your own. Focus on three verification points:

Certification badges: Look for ISO 9001, VDA 6.3, or industry-specific standards on company pages. These prove operational quality.

Inquiry conversion rate: Active suppliers handle 3-5 new inquiries per week. Check their response time metrics if displayed. Under 24 hours beats the platform average.

Customer testimonials: IndustryStock allows verified buyers to leave feedback. Companies with 3D product animations and detailed specs get 40% more inquiries. These sellers invest in their platform presence. They handle orders with care.

Prioritize Russian and German suppliers. IndustryStock dominates both markets. Local suppliers ship faster to German foundries. Cross-border VAT complications vanish.

Conclusion

Germany has plenty of options for high-temperature ceramic foam filters. Running a precision foundry in Munich? Managing Metal casting in Hamburg? You’ll find what you need here. Ludwig Föbus in Gütersloh specializes in these filters. Giessereitechnik Wystrach covers the whole country. You now have a clear map of trusted partners.

The real advantage? You’re not stuck with one vendor. VHG runs warehouses in multiple locations. This means fast delivery across regions. IndustryStock makes it easy to compare specs and prices from different suppliers at once. You save time and money.

Your next step is simple: Find which supplier fits your needs best. Look at their locations and technical skills. Match them with what you need.

Need custom filtration? Contact FoundryMax or KERAFOL. Need quick availability and good prices? Use IndustryStock’s system. It connects you with several verified suppliers at once.

Your castings are only as good as your filters. Choose the right supplier. Source smart.