Let’s getting real. Finding a ceramic foam filter supplier takes no time. Finding a great one? That’s the challenge. Manufacturers all promise the best porosity. They claim high thermal shock resistance and low prices. Ask any foundry engineer, though. A datasheet and the pouring floor often tell two different stories.

Your supplier impacts your scrap rates and profits. The right choice stabilizes your casting quality. The wrong choice brings headaches. You face clogged filters. Inclusions ruin parts. Delivery dates slip. You aren’t just buying a consumable here. You need a partner who understands your metal.

We analyzed five market leaders to clear things up: SF-Foundry, SELEE, LANIK, FoundryMax, and DTYR. We don’t just list specs. We break down strengths and weaknesses. We show which foundry type they serve best. Maybe you need engineering support. Or perhaps you need cost savings for big runs. This comparison helps you decide who earns your business.

SF-Foundry

SF-Foundry hasn’t shared performance data we can confirm. So compare their products against industry standards:

For aluminum casting filters, ask for specs showing:- Pore densities between 10–60 PPI. Look for uniformity (±2 PPI tolerance across batches)- Thermal stability up to 1000–1200°C with cycle test results- Filtration efficiency data: 50–80% inclusion reduction. This needs verification through metallographic analysis before and after filtering- Hydrogen reduction capability: Density Index should improve from 8–10% down to 3–5% with degassing

For iron and steel casting, require proof of:

– Lower PPI ranges (10–30 PPI) built for high-temperature ferrous alloys

– Thermal shock resistance above 1500°C with multi-cycle durability tests

– Real improvements in impact toughness, fatigue life, or X-ray pass rates in finished castings

Make a Smart Choice

SF-Foundry contacts you? Treat them like any new supplier. Use the same strict vendor checks. Ask for sample filters for in-house trials. Run side-by-side tests with your current supplier. Measure real defect rate drops in your production.

SELEE Corporation

SELEE Corporation joined the ceramic foam filter market decades ago. They built a strong name in aluminum, iron, and steel filtration. This North Carolina company now works under Porvair plc’s Aerospace & Industrial division. Manufacturing happens in Hendersonville and China. This setup serves foundries worldwide.

Product Range and Technical Capabilities

SELEE groups its filters by metal type and working temperature:

Aluminum casting filters use alumina-based ceramic foam. Standard products include:

– PPI options from 10 to 50, with tighter tolerances (±2 PPI) than many competitors

– Size accuracy within ±1.0–2.0 mm on length and width, ±0.5–1.0 mm on thickness

– Working temperatures up to 1000–1200°C for typical aluminum alloys

– Open porosity rates that keep flow steady across batches

Iron and steel filters use zirconia chemistry for high-heat stability:

– Lower PPI ranges (10–30 PPI) built for thick ferrous metals

– Max continuous use above 1500°C with proven thermal shock cycles

– Stabilizers like MgO, CaO, or Y₂O₃ in the ZrO₂ matrix cut reactivity with alloy elements

– Special versions for stainless steel, carbon steel, and nickel-base superalloys

Engineering Support and Standards

SELEE offers application engineering that many mid-tier suppliers don’t. Their technical teams assist with:

-

gating system design matched to filter size and metal flow rates (listed in kg/s or kg/min)

-

Preheat protocols based on metal temperature and filter thermal mass

-

Filter sizing math using actual casting weight, pour time, and needed filtration efficiency

The company shares test methods for pressure drop versus flow and strength. This openness helps buyers compare options easily across multiple suppliers.

What SELEE Does Well

Their dual-continent setup (US and China) cuts lead times for North American and Asian buyers. Standard filters ship within 2–4 weeks. Custom sizes or special chemistries take 4–6 weeks.

Proven filtration performance sets SELEE apart from unclear competitors. Defect reduction rates vary by foundry and alloy. But they share case studies showing real inclusion removal and lower scrap rates. Technical papers and patents show pore structure controls and mechanical properties with real numbers—not vague claims.

Alloy-specific tuning helps steel and superalloy casters. SELEE adjusts filter chemistry to limit reaction with specific alloy elements. This stops contamination that basic filters can cause.

Considerations Before Ordering

SELEE runs within a larger corporate group (Porvair plc). Some foundries like the financial backing. Others notice slower decisions than with independent filter makers. Ask for clear delivery dates and emergency contacts if your production schedule is tight.

Pricing falls in the mid-to-premium range. You pay for engineering help and stricter quality control. Cost-focused shops might find cheaper options, but expect less technical guidance.

SELEE fits best for foundries that want technical partnership over basic buying relationships. Your team needs filtration advice, tested performance data, and reliable global delivery? SELEE belongs on your shortlist.

LANIK

LANIK is based in Spain. The company makes ceramic foam filters for foundries across Europe and Latin America. They focus on iron, steel, and aluminum casting. Their tech center in northern Spain creates filter formulas that match European foundry standards and metal types. ISO-certified facilities produce filters for high-volume die-casting plants and smaller job shops.

Product Lines by Metal Type

LANIK groups its catalog by metal type:

Gray and Ductile Iron filters use alumina-silicate ceramics with:- PPI ranges from 10 to 30, optimized for ferrous metal viscosity- Operating temperatures up to 1550°C continuous use- Standard square formats (50×50 mm to 300×300 mm) and custom wedge shapes for runner systems- Chemical stability against sulfur and phosphorus in iron melts

Aluminum casting filters feature pure alumina matrices:

– Higher porosity options (20–50 PPI) for low-density alloy flow

– Thermal shock resistance tested across 300+ cycles at 750–850°C

– Works with fluxed and degassed melts, including TiB grain refiners

– Available in round discs for launder systems and rectangular blocks for gating filters

Steel and special alloy filters use zirconia-based compositions:

– Low PPI (10–20) with reinforced cell walls for heavy-section castings

– Maximum temperatures above 1650°C for carbon steel and tool steel grades

– Inert formulas that limit reaction with chromium, nickel, or molybdenum

– Custom geometries for continuous casting tundishes and batch ladle filters

Engineering and Customization Services

LANIK works with foundry engineers to match filter specs to gating designs. Their team calculates metal flow rates. They estimate pressure drop. They recommend filter placement in the running system. This cuts down trial-and-error during new product launches.

Custom filter shapes ship within 4–6 weeks. LANIK machines non-standard profiles. They add preheating channels. They create multi-layer porosity gradients. Minimum order quantities for custom work start at 100–200 pieces, depending on complexity. Standard catalog items ship in 1–2 weeks from European stock.

Regional Strengths and Practical Limits

European foundries get local stock and fast response. LANIK’s location cuts shipping time and freight costs versus Asian suppliers. Technical visits happen within days, not weeks. Documentation meets EU regulations—REACH, RoHS, and material safety data sheets in local languages.

Latin American customers get LANIK through regional distributors. Lead times stretch to 6–8 weeks due to ocean freight and customs. Some foundries face inventory planning issues during peak seasons.

LANIK pricing sits in the mid-range. You pay less than premium German or US brands. But you pay more than direct-import Chinese filters. The trade-off: consistent quality, engineering support, and shorter emergency restocking cycles for European operations.

LANIK fits foundries that want regional partners and hands-on help. Does your plant run complex alloys? Need custom filter shapes? Want a supplier within driving distance for audits and troubleshooting? LANIK is worth a look. Request sample filters. Run melt trials. Compare inclusion removal against your current supplier before placing volume orders.

FoundryMax

FoundryMax entered China’s foundry filtration market over twenty years ago—around 2003–2005. They built their expertise in ceramic Foam filters and fiberglass mesh products. The company sees itself as an application-focused supplier, not just a product vendor. Their model centers on custom R&D, on-site technical support, and hands-on troubleshooting. This reduces casting defects. Mid-sized foundries running ferrous and non-ferrous alloys are their main target. These shops need practical solutions more than brand prestige.

Product Portfolio and Technical Specs

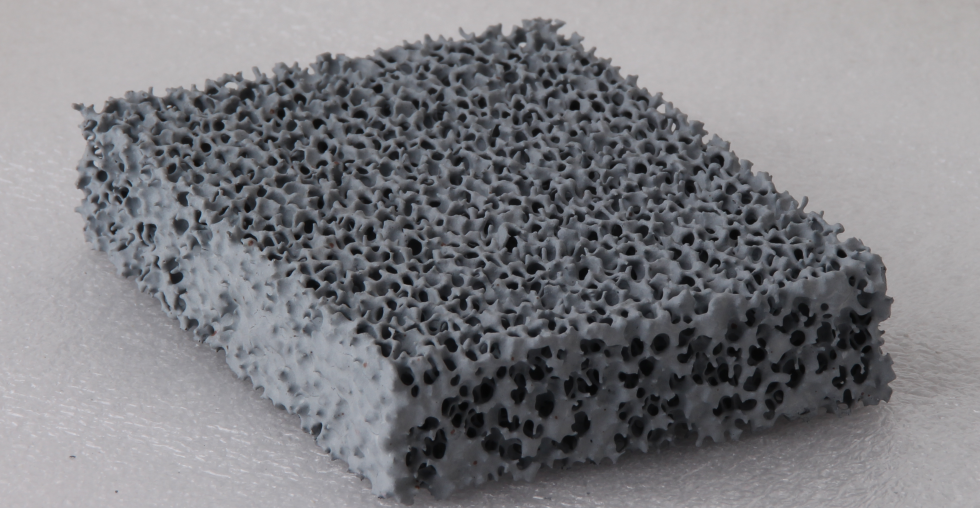

Ceramic foam filters form the core offering. Material systems align with Chinese foundry needs:

-

Alumina-based foams for steel and high-temperature alloys, operating above 1600°C

-

Zirconia formulations for precision steel castings that need ultra-clean metal

-

silicon carbide (SiC) filters optimized for ductile iron, grey iron, and some copper alloys

-

Alumina-silicate compositions for aluminum die-casting and gravity casting

Pore density range runs from 10 to 60 PPI:

– 10–20 PPI handles large steel or iron castings. Flow rate matters most here.

– 20–30 PPI balances filtration efficiency and pressure drop. Good for general iron and aluminum work.

– 30–60 PPI suits high-cleanliness applications. Think bronze, brass, or precision aluminum parts.

Standard sizes span 40×40 mm up to 600×600 mm squares. Thickness options run 22–50 mm for routine jobs. Thicker sections are available for heavy steel pours. Custom geometries ship within 4–6 weeks for orders above 100 pieces.

Fiberglass mesh filters complement ceramic products. Use them for aluminum and short-contact ferrous applications:- Mesh openings from 0.5–3.0 mm depending on alloy viscosity- Basic weights between 60–300 g/m² with resin or alkali-resistant coatings- Temperature limits reach 800–900°C for aluminum, 1250–1450°C for brief steel contact- Available as pre-cut squares (50×50 to 150×150 mm) or rolls (0.9–1.2 m wide, 50–100 m long)

Performance Data and Real-World Results

FoundryMax claims 60–90% inclusion reduction. This is measured by area or particle count versus unfiltered metal. Defect rates drop 20–60% with correct filter integration. That means good gating design and metal treatment. These ranges match industry norms. But results vary based on alloy chemistry, pouring temperature, and mold system cleanliness.

Pressure drop curves exist for specific alloy families. Request detailed flow data for your metal grade and casting weight before you specify filter size. Generic charts don’t account for superheat, inoculant additions, or flux residues in your process.

Production Capacity and Supply Chain

A twenty-year-old Chinese ceramic filter plant produces several hundred thousand pieces per month across all product lines. FoundryMax operates at this scale based on their experience and product breadth. Standard catalog items ship within 1–2 weeks from Chinese warehouses. Custom orders take 4–6 weeks. This depends on tooling and batch scheduling.

Quality certifications aren’t detailed on their website. Verify ISO 9001 credentials before you buy. Request batch test reports. These include thermal shock cycles, compressive strength, and porosity uniformity. Audit production facilities before you commit to volume contracts.

Cost Positioning and Value Trade-offs

FoundryMax pricing sits in the lower-to-mid range. Compare this to European or North American brands. You save 30–50% versus SELEE or German suppliers. The trade-off? Better technical documentation. You get application engineering help. Plus, batch quality is more consistent than the cheapest options.

Engineering support includes gating system reviews and filter placement recommendations. They also do troubleshooting visits for persistent defect issues. This service level beats pure trading companies. But it falls short of global players with dedicated R&D centers and metallurgical labs.

Best-Fit Customer Profile

FoundryMax works well for cost-conscious foundries that still need technical guidance. Does your plant run multiple alloy families? Need responsive local support within China or nearby Asian countries? Want to cut filter costs without losing all technical backup? FoundryMax deserves evaluation alongside other mid-tier suppliers.

Request samples for side-by-side trials. Run controlled pours with your current filters and FoundryMax products. Measure scrap rates. Check X-ray pass rates. Track mechanical properties in finished castings. Also track total landed cost. This includes freight, lead times, and emergency reorder capability. This data-driven comparison shows whether FoundryMax delivers value beyond initial price savings.

Direct verification matters. Contact FoundryMax for current certifications, capacity figures, and customer references in your casting sector. Third-party validation is limited for this supplier. So your own due diligence protects production continuity. It also protects quality commitments to your customers.

DTYR Filters

DTYR Filters began making ceramic foam filters in 1997. That’s over twenty-five years of filtration products made in China. The company works as an OEM/ODM partner for overseas distributors and foundry customers. Export markets bring in major revenue. Products ship to North America, Europe, and Southeast Asia. DTYR focuses on mid-tier foundries that run aluminum gravity casting, low-pressure die-casting, and iron pour operations.

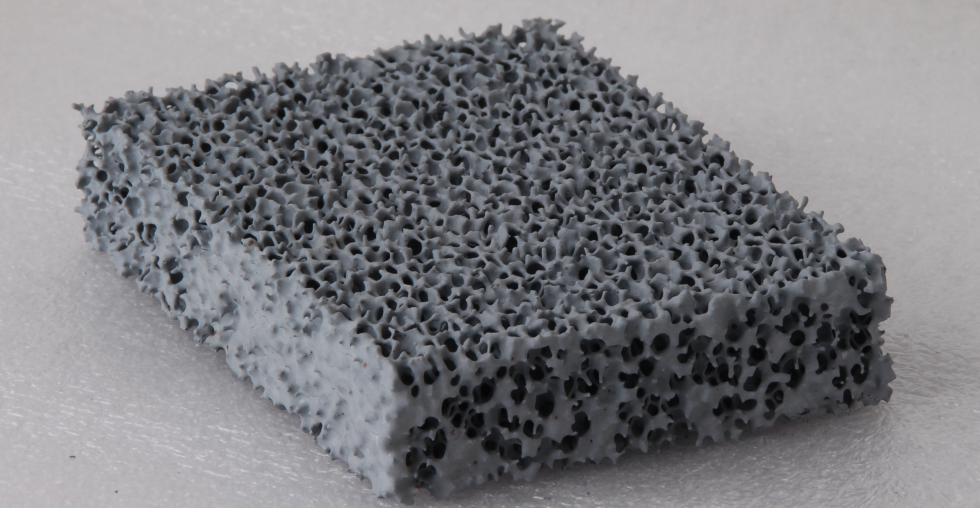

Product Range and Material Systems

DTYR makes three main ceramic types:

Alumina (Al₂O₃) filters work for aluminum and Aluminum Alloy casting:- Working temperatures from 720–780°C fit standard aluminum pour ranges for A356, A380, and similar alloys- PPI options span 20–60. You’ll find 30 PPI common for general gravity casting. 50–60 PPI suits high-cleanliness die-casting- Standard squares run 50×50 mm to 300×300 mm. Custom shapes include rounds and trapezoids for launder systems

Silicon carbide (SiC) filters handle grey iron, ductile iron, and some steel jobs:

– Temperature range covers 1350–1550°C for standard ferrous casting

– Lower PPI range (10–30) fits iron’s thicker flow. 10–20 PPI works for large-section castings. 30 PPI suits hydraulic parts and automotive components with stricter cleanliness needs

– Filtration data shows performance by size. A 40×40×22 mm SiC filter processes 64 kg of molten iron at 1.5 kg/cm² pressure drop. Larger formats (150×150×50 mm and up) handle hundreds of kilograms per filter

Zirconia (ZrO₂) Filters work for precision steel and superalloy casting where contamination needs to stay minimal. Temperature stability goes beyond 1650°C. These cost more than alumina or SiC types but give you ultra-low inclusion counts.

Custom Engineering and Size Flexibility

DTYR makes filters from 40×40×22 mm up to 600×600 mm squares. Thickness ranges from 22–50 mm for standard work. Thicker sections exist for heavy-section steel castings. Custom shapes ship within 4–6 weeks. Minimum orders start around 100 pieces for non-standard shapes. Engineers work with foundries to match filter size to gating design and metal flow rates.

The company supplies filters made for refractory filter boxes and steel gating frames. Edge chamfers and compression heights adjust to fit your tooling. This reduces trial-and-error during new product setup.

Market Position and Practical Limits

DTYR pricing sits in the budget-to-mid range. You pay less than known Western brands. But quality control and papers don’t match top-tier suppliers. Request ISO 9001 certificates. Ask for batch test reports that show thermal shock resistance and pore uniformity. Check these documents before placing volume orders.

DTYR’s OEM/ODM focus means they work through distributors. Direct factory contact exists but technical support depth varies. Don’t expect the same engineering help as SELEE or LANIK. For simple jobs—standard aluminum gravity casting or routine iron work—DTYR gives you working filters at good prices. Complex alloys or critical aerospace-grade castings? Look elsewhere.

DTYR fits cost-focused foundries running proven processes. Order samples. Run side-by-side trials against your current supplier. Measure defect rates and filter life under your actual pouring conditions. Compare total landed cost including freight and lead times. This shows whether DTYR’s price edge holds up in real production.

The Final Verdict: Who Should You Call?

So, who wins? The truth is, there isn’t one clear winner for everyone. Your “best” supplier depends entirely on what your foundry values most right now: deep engineering support, regional speed, or cost efficiency.

Here is how we see the landscape:

-

Choose SELEE if your casting geometry is complex and you need an engineer on speed dial. You pay a premium, but for critical superalloy or aerospace parts, their technical backup is an insurance policy you probably need.

-

Choose LANIK if you operate in Europe or Latin America and want a balance of proximity and performance. They are the solid, reliable choice for standard iron and aluminum work without the trans-oceanic shipping headaches.

-

Choose FoundryMax if you want to cut costs without sacrificing quality documentation. They offer a smart middle ground—significantly cheaper than Western brands, but with better tech support and consistency than generic trading companies.

-

Choose SF-Foundry if you have a stable, standard process (like gravity die casting) and budget is your main driver. Just be prepared to handle the technical side yourself.

The bottom line? Don’t bet your production entirely on a datasheet. Pick two suppliers from this list. Order samples. Run a split test on your pouring floor next week coverage. The scrap pile never lies—it will tell you exactly who deserves your order.